Storage & Handling

The methods of storing and handling conveyor belting and the procedures for tensioning it before making the final splice are just as important as actually making the splice. Protect your conveyor belt investment with proper storage. Belts should always be stored upright in the factory package until used in a cool, dry building and in an area free from sunlight. Store the belt roll suspended on a tube, bar or support stand. Under no conditions should rolls of belt, especially raw edge or used, be laid flat on its side. Storing the belt flat on the ground, where moisture can penetrate exposed fabric, or storing the belt roll with weight on one edge, may stretch the belt. This can cause belt camber or a bowing in the belt, resulting in serious belt mistracking.

During extended storage, the belt roll should be covered with a tarp or dark plastic. Exposure to sunlight, rain and ozone can have detrimental effects on the rubber covers. The cover should remain in place for the entire storage time. Ideally, the belt should be rotated 90 degrees approximately every 90 days. Rotation should be performed in the same direction used to wind up the belt. Rotating in the opposite direction could cause the roll to loosen or telescope.

As the length of time stored increases, and as the size of the roll of belting increases, so does the importance of the following correct storage procedures. Following these procedures will increase the life of the belt once it is installed on the system.

Conveyor belting is customarily packaged in cylindrical reels, or rolls on a core with the carrying cover side facing out. If rolling is necessary, it should occur in a direction such that the end of the roll on the outside wrap travels in the direction from which it is wound up. Rolling in the opposite direction tends to loosen and telescope the belt.

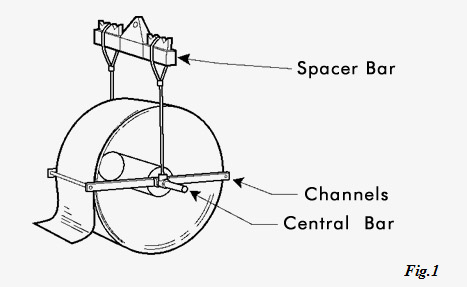

Reels or rolls should never be dropped from a freight car, truck, or other means of conveyance, since their weight will break the packaging and may damage the belt. Reels or rolls should always be rolled, or provision should be made for hoisting them. For hoisting, a square lifting bar of the correct size should be placed through the hole in the center of the core. A spreader bar should be utilized to prevent the chains or slings from damaging the edges of the conveyor belt. Slings or chains of the correct size for the weight of the roll should be used (Fig. 1).