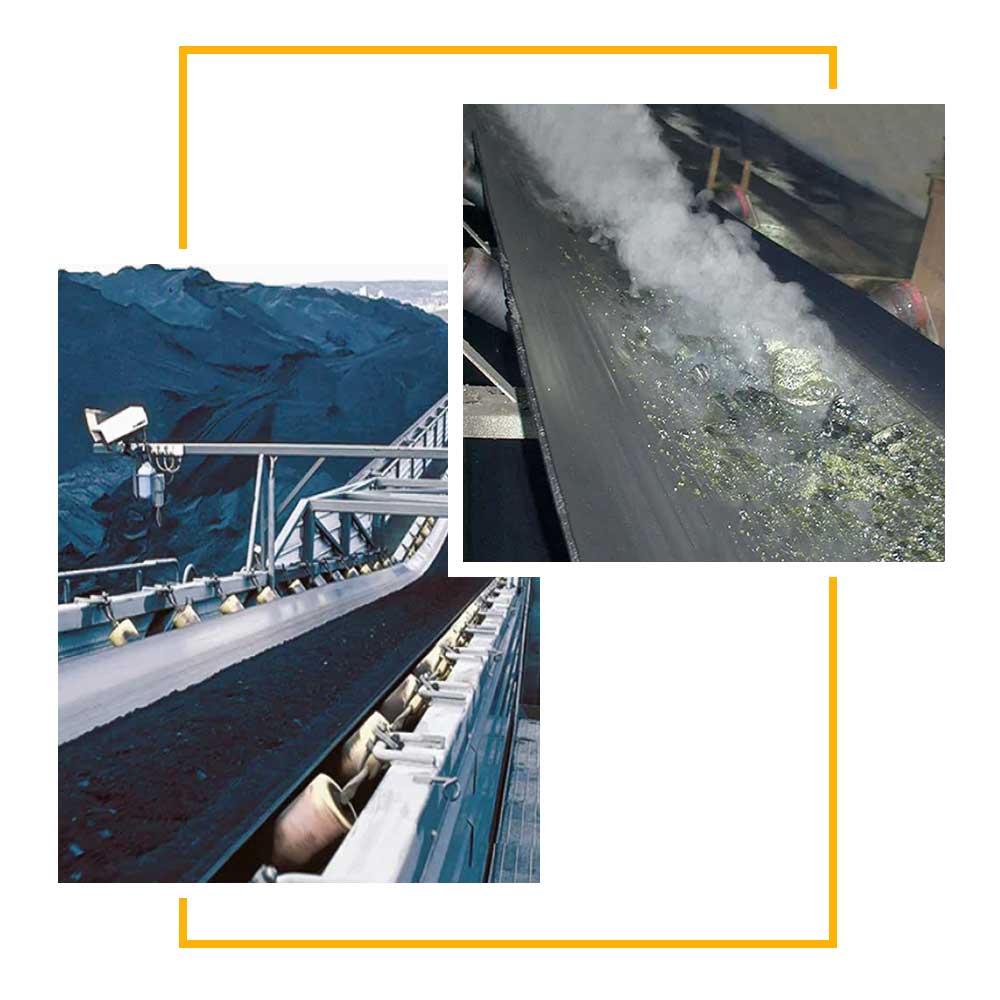

1. General Duty Conveyor Belts

General duty rubber conveyor belts are versatile, robust belts designed for a range of industrial applications. Typically used for transporting materials in bulk, these belts can be supplied in different carcasses, namely, cotton, Nylon-Nylon, Polyester-Nylon (EP), offering durability and resistance to abrasion. They are suitable for handling materials such as gravel, coal, and aggregates, and are commonly employed in industries like mining, coal handling, crushers, construction, and manufacturing.

General duty rubber conveyor belts provide reliable performance under moderate to heavy loads, and their flexibility and strength make them ideal for various conveyor systems.

2. Chevron Conveyor Belts

Chevron rubber conveyor belts are specially designed to handle inclined or steep-angle conveying of bulk materials. Featuring a distinctive V-shaped or chevron pattern on the belt’s surface, these belts effectively prevent material slippage and ensure stable, efficient transport. They are ideal for moving materials such as grains, rocks, bags, or aggregates on inclines up to 40 degrees.

Made from durable rubber compounds, chevron belts offer excellent resistance to wear and abrasion, ensuring a long service life. Their design enhances grip and minimizes the risk of material spillage, making them a reliable choice for challenging conveyor applications.

3. Bucket Elevator Conveyor Belts

Elevator rubber conveyor belts are engineered for vertical lifting applications, designed to transport bulk materials efficiently from one level to another. These belts feature a series of rubber or fabric-reinforced buckets or cups attached to a durable rubber belt, allowing for the smooth, reliable movement of materials like grains, powders, and minerals. Built to withstand high lifting pressures and abrasive materials, elevator belts offer robust performance and longevity. They are ideal for industries such as agriculture, mining, and manufacturing, where vertical conveying is essential for optimizing space and handling bulk material efficiently.

4. Food Grade Conveyor Belts

Food grade rubber conveyor belts are specifically designed to meet stringent hygiene and safety standards for handling edible products. Made from high-quality, non-toxic rubber compounds. They feature smooth, easy-to-clean surfaces that minimize bacterial growth and ensure compliance with food safety regulations. Ideal for applications in the food and beverage industry, food grade rubber conveyor belts provide reliable, sanitary transport for a wide range of food items, from raw ingredients to finished products, while maintaining strict hygiene standards.

5. Heat Resistant Conveyor Belts

We offer heat resistant rubber conveyor belts that are engineered to withstand high temperatures ranging from up to 300°C, making them ideal for applications involving hot materials or processes. These belts are made from specially formulated rubber compounds that resist thermal degradation, ensuring durability and performance under extreme heat conditions. They are commonly used in industries such as metallurgy, cement, and glass manufacturing, where high-temperature environments are prevalent. With their robust construction, heat resistant rubber conveyor belts maintain structural integrity and efficient material handling, even in the face of intense heat.

6. Oil Resistant Conveyor Belts

The carcass material of the oil-resistant conveyor belt is EP which is a polyester-nylon blend. It has good adhesion and strong resilience to ripping and tearing in addition to its high levels of strength and low stretch. The surface material for the covering layer is typically made of nitrile butadiene rubber, abbreviated as NBR, giving better layering to the belt. We offer high-quality oil-resistant conveyor belts using such material only.

These belts prove to be the best for many cooking, and electric power plants utilize these oil-resistant conveyor belts to transport machine oil-coated components and parts as well as heavy-oil-treated coal for cooking. Transporting non-polar organic solvents and fuel, such as soybean draff and fish flesh, is no problem for these oil-resistant belts.

7. Chemical Resistant Conveyor Belts

Chemical resistant rubber conveyor belts are designed to handle environments where exposure to corrosive substances, acids, and alkalis is common. These belts are made from advanced rubber compounds that offer exceptional resistance to chemical attack, ensuring they maintain their structural integrity and performance even in harsh chemical environments. Ideal for industries such as chemical processing, pharmaceuticals, chemical fertilizers, paper mill, mining, and waste management, chemical resistant conveyor belts provide reliable and durable material handling solutions while preventing contamination and ensuring long-lasting operation.